Farm Workshop: 10 Shocking Safety Tips Revealed!

“Over 60% of farm injuries occur in workshops lacking proper safety protocols and organized tool storage.”

Introduction: Why Farm Workshop Safety Matters

In today’s fast-evolving agricultural landscape, the farm workshop stands as the backbone of equipment maintenance, machinery repairing, and daily operational readiness. As we progress towards more productive and sustainable farming systems, our attention must be drawn to the design, functionality, and, most importantly, the safety of our farm workshops. Establishing a well-designed workshop—not just a shed full of tools, but a thoughtfully organized workspace—drastically improves productivity, reduces downtime, and enhances the longevity of our agricultural equipment.

With agricultural activities becoming more complex and technology-driven, the potential hazards in workshops have increased. Serious accidents can occur due to poor organization, inadequate safety protocols, and improper maintenance practices. That’s why we must arm ourselves with cutting-edge workshop safety tips and proven organizational strategies.

In this in-depth guide, we reveal 10 shocking safety tips that can transform your farm workshop into a bastion of productivity, safety, and equipment efficiency. Whether you are designing a new workspace or upgrading an existing one, our actionable insights and step-by-step planning tips will help you establish a workshop that truly supports the diverse needs of modern agriculture.

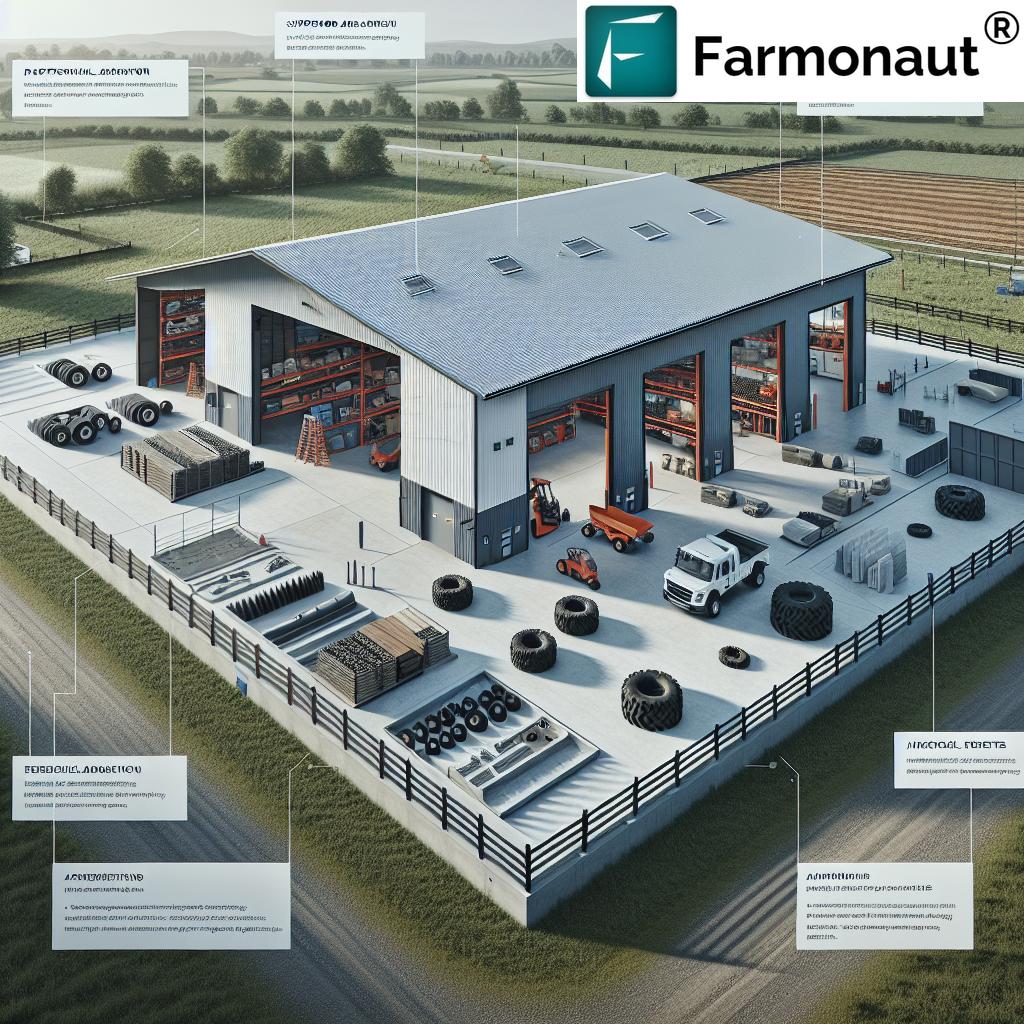

Designing an Efficient Farm Workshop

The cornerstone of any productive farm operation is a workshop tailored for easy equipment access, safe movement, and seamless workflow. When considering farm workshop design for your farmstead, we should focus on several core principles:

- Functionality and Adaptability: Ensure that the workshop is adaptable to evolving agricultural activities and the changing sizes of farm equipment.

- Strategic Location: Central placement within the farmstead shortens travel times, reduces logistics overhead, and enhances day-to-day operational efficiency. This is supported by FAO’s comprehensive workshop guidelines.

- Optimal Size: The workshop should accommodate your largest machinery with additional clearance for storage, movement, and repairs. Always provide buffer space for tool storage and future expansion.

- Accessibility: Large, wide doors allow easy movement of tractors and implements. Clear, well-marked driveways and loading areas are essential.

By investing early in comprehensive farm workshop layout planning, you create a safe, organized hub for operational excellence.

Want to track your crop health and workshop assets from anywhere? Get the Farmonaut app—available for Web, Android, and iOS!

Optimizing Workshop Layout and Zoning for Maximum Efficiency

A highly functional workshop layout is more than just aesthetics—it’s about workflow optimization, organization, and integrating clear zones for specific tasks. The goal is to minimize disruptions and support a logical, ergonomic flow of work:

- Equipment Storage Area: Designate at least one section for heavy vehicle and machinery storage. Ample space prevents accidental bumps, improper stacking, or scraping, safeguarding sensitive components.

- Maintenance and Repair Zone: This area should be spacious enough for complete disassembly of your largest piece of equipment, with workbenches and key tools nearby.

- Tool and Part Storage: Utilize high-quality racks, shadow boards, and labeled bins for tool storage and organization for farms. Clearly marked areas improve accessibility and reduce search time.

- Cleaning Station: Install wash-down bays and drainage to enable effective cleaning of equipment after use, reducing rust and contamination risks.

- Welding and Fabrication Bay: In this specialized zone, ensure high-grade ventilation and spark-resistant flooring. Keep metal stock and welding tools within arm’s reach.

We recommend referencing Bultmor Buildings’ workshop zoning guide for more layout ideas.

“Regular equipment maintenance can extend machinery lifespan by up to 40% in well-designed farm workshops.”

Essential Utilities and Infrastructure Considerations

For optimum agricultural equipment maintenance and operational efficiency, infrastructure planning must never be overlooked. Let’s review the nonnegotiables that set the foundation for a safe working environment:

- Electrical Capacity: Size your electrical system for future growth—heavy-duty circuits for compressors, welders, and lighting. Use weatherproof, GFCI outlets in wet zones.

- Lighting: Uniform, high-CRI (Color Rendering Index) LED lighting allows for detail work even during night repairs. Well-lit areas minimize slip, trip, and cut risks. Explore best practices at Texas Real Food’s lighting guide.

- Ventilation: Proper workshop ventilation and lighting is vital, especially for welding, painting, or operating fuel- or chemical-powered tools. Install roof ventilators, exhaust fans, and cross-ventilation windows for healthy air quality.

- Water Supply and Drainage: Clean running water enables quick cleaning and first aid, while dedicated drains prevent flooding during equipment wash-downs.

- Fire Suppression: Integrate fire extinguishers and blankets throughout the workshop, especially near the welding bay and oil storage. Install smoke detectors and, where possible, sprinkler systems.

Top Essential Farm Workshop Tools

Outfitting your workshop with essential farm workshop tools directly impacts how quickly and safely you can handle daily maintenance, repairing, and even large-scale fabrication. Let’s explore what no productive agricultural workshop can do without:

-

Air Compressor: A versatile workhorse, the air compressor powers pneumatic devices like impact wrenches, paint sprayers, and tire inflators. It’s especially useful for operating grease guns (for regular maintenance) and removing stubborn bolts.

(See more on best-in-class compressors in the Farmonaut Essential Workshop Tools Guide.) -

Workbench with Vice: The central station for repairs—a sturdy workbench makes precise cutting, cleaning, and inspection of parts straightforward. A robust vice offers secure gripping of metal, wood, or small components.

See organization tips at Growing Farmers’ tool list. -

Welding Equipment: From MIG and TIG to stick welders, welding is indispensable for frame repairs, fabricating brackets, and mending implements. Choose the welding type based on thickness and materials handled most frequently in your operation.

Find MIG vs. TIG recommendations on the Farmonaut’s expert guide. -

Cordless Tools: Modern, portable cordless tools, such as drills, grinders, and saws, add tremendous flexibility and can be quickly recharged for use anywhere—ideal when you need to do quick fixes in the field, away from the main bay.

Efficiency tips at Growing Farmers’ guide. -

Fencing Tools: Specialized tools (fence-post drivers, fencing pliers, wire tensioners) save huge amounts of time on farm boundary maintenance, repairs, and new installations.

Key fencing tools explained at Agrifood SA. -

Angle Grinder: Exceptional for cutting, smoothing, and shaping metal and other materials, angle grinders extend the lives of parts and facilitate rapid component fabrication.

Tool selection details at Farmers Journal tool list. - Jack and Wheel Dolly: Critical for lifting and moving heavy agricultural machinery, these tools ensure safe tire changes and facilitate undercarriage maintenance with minimal risk of personal injury.

A well-curated toolkit not only improves job speed but also contributes to your operation’s productivity and storage organization, which in turn enhances overall safety.

Interested in automating fleet movement, improving logistics, and minimizing downtime? Explore Farmonaut Fleet Management for satellite-based agricultural vehicle and asset tracking. Efficient fleet oversight boosts field operation productivity and farm workshop scheduling!

Equipment Maintenance in Farm Workshops: Key Practices for Longevity

Sustaining the performance and longevity of your farm tools and machinery hinges on regular maintenance. Effective maintenance not only reduces breakdowns but also ensures a safer environment for all workshop users. Here’s how we focus on proactive care:

- Cleaning and Lubrication: Routine cleaning clears away damaging dirt, mud, and residues. Special attention must be paid to lubricating all moving parts to prevent friction and rust. For agricultural equipment used frequently, we recommend establishing a cleaning protocol at the end of each use cycle.

- Sharpening and Timely Replacement: Blades, knives, and cutting edges should always be sharp. Dull implements increase injury risk and decrease productivity. Replace cracked, bent, or excessively worn parts instead of risking dangerous failures.

- Storage and Organization Best Practices: Implement racks, labeled drawers, and climate control where possible. Dry, aerated storage reduces metal corrosion and keeps sensitive electronics safe. Consistent tool organization saves you money, as fewer tools get lost or damaged.

Did you know? Thorough routine maintenance can extend machinery life by up to 40%. This demonstrates the significant return on investing time in equipment care!

Want to make your entire supply chain transparent and secure?

Discover Farmonaut Traceability Solutions—enabling blockchain-based product tracing, verification from farm gate to table, and reducing fraud for agricultural operations.

Farm Workshop: 10 Shocking Safety Tips Revealed!

Ensuring farm workshop safety is not just about complying with regulations—it’s about protecting our team, our assets, and the continuity of agricultural activities. Too often, workshops become the source of accidents, injuries, and equipment damage due to overlooked details. Below are the 10 shocking safety tips every farm workshop must implement:

-

1. Isolate Your Welding Area Properly

Welding emits dangerous fumes and fire risks. Create a dedicated bay with spark-resistant floors, fireproof curtains, and forced-air ventilation. Always keep a fire extinguisher within reach. -

2. Store Flammable Materials in Approved Cabinets

Oils, fuels, paints, and solvents must be stored in flame-resistant, lockable cabinets well away from welding bays or open flames. Clearly label each cabinet. -

3. Implement Personal Protective Equipment (PPE) Policies

Mandate ppe—gloves, safety glasses, steel-toe boots, welders’ shields—before any workshop operation. Regularly inspect PPE and provide clear signage on their necessity. -

4. Install First Aid and Eye Wash Stations

Immediate access to first aid kits and eyewash stations can prevent permanent injuries. Place these at clear, marked locations near hazardous work zones. -

5. Plan Clear Emergency Exits and Mark Escape Routes

All workshop personnel should be able to exit quickly in the event of fire, chemical spills, or other emergencies. Use glow-in-the-dark signs and regularly run evacuation drills. -

6. Dedicate Zones for Tool Storage and Waste Management

Random tools or rags are trip hazards and fire risks. Keep all tools organized in racks or drawers and provide steel bins for oily waste. -

7. Use Lockout/Tagout Procedures on Machinery

Before performing equipment maintenance or repairs, lock the power source and attach tags warning others not to operate the machinery. This protocol prevents unexpected energizing. -

8. Maintain Slip-Resistant Flooring and Immediate Spill Response Kits

Use anti-slip floor coatings and rubber mats. Any spill (oil, water, chemicals) must be cleaned immediately. Spill kits should be present and used as first response. -

9. Check and Replace Fire Extinguishers Periodically

Fire extinguishers must match the types of fire risks (electrical, oil, chemical). Monthly checks ensure pressure and readiness. Log all inspections. -

10. Train All Staff on Safety Protocols and Emergency Response

Knowledge is power. Organize regular safety briefings, hand out written protocols, and ensure every worker knows what to do in a crisis (fire, cut, poisoning, etc.).

Safety Tip Implementation & Impact Table

| Safety Tip | Implementation Steps | Estimated Time (hrs) | Equipment Needed | Estimated Cost (USD) | Safety Improvement Index |

|---|---|---|---|---|---|

| Isolate welding area with ventilation | Erect walls, install fire curtains, fume extractor, fire extinguisher | 8 | Curtains, exhausts, signage, extinguisher | $1,200 | High |

| Store flammables in fire-rated cabinets | Install cabinets, label, relocate chemicals | 4 | Fireproof cabinets, labels | $500 | High |

| Mandate PPE usage | Stock PPE, display signs, conduct checks | 2 | Gloves, goggles, boots, shields | $400 | High |

| Install first aid & eye-wash stations | Buy kits, mount wall units, signpost stations | 2 | First aid kits, eye wash units | $350 | High |

| Create marked emergency exits | Install luminous signs, clear pathways, drill practice runs | 6 | Exit signage, paint, benches (for training) | $200 | High |

| Organize tool storage & waste bins | Set up racks/drawers, label, assign bin zones | 7 | Tool racks, bins, labels | $350 | Medium |

| Implement lockout/tagout procedures | Draft protocols, get lockout kits, train staff | 5 | Lockout kits, posters | $300 | High |

| Lay slip-resistant floors & spill kits | Apply coating, place mats, stock kits | 8 | Matting, coating, spill kits | $800 | Medium |

| Check/replace fire extinguishers | Monthly inspection, replace expired units | 1 (recurring) | Extinguishers, logbook | $150/year | High |

| Safety and emergency protocol training | Develop materials, organize workshops, quizzes | 12 (initial) | Printed protocols, instructor | $500 | High |

Workshop Safety Protocols and Emergency Procedures

Implementing robust safety protocols is essential for not only regulatory compliance but also the peace of mind that comes from knowing everyone can act swiftly and correctly, even under pressure. Some cornerstone steps include:

- Daily Workshop Inspection: Walk through all areas, checking tool placement, exits, PPE accessibility, and operational readiness.

- Fire Safety Readiness: Position fire extinguishers in high-risk areas, check expiry monthly, and hold quarterly fire drills.

- Emergency Lighting and Escape: Ensure exits are never blocked, battery-powered emergency lights are tested monthly, and signage is maintained.

- Clear Emergency Protocols: Post illustrated procedures for fire, electrical shock, chemical exposure, and equipment malfunction at every zone.

- Mandatory Training: Schedule annual workshops covering lockout/tagout, first aid, and machine safety for every farm workshop member.

Tip: Top-tier Farmonaut Crop Loan & Insurance services leverage satellite-verifiable records, which streamline insurance claims after equipment-related incidents, reducing fraud and ensuring financial support when you need it.

Preventing Rust on Farm Tools & Asset Loss

Rust rapidly destroys both the appearance and structural integrity of farm tools—threatening user safety and tool lifespan. Best practices include:

- Clean and oil high-use tools after every session, especially during high-humidity periods.

- Store cutting and sharpening tools in silicon-coated sleeves or oiled rags inside dry, ventilated cabinets.

- Organize metal tools on wall-mounted racks—keeping airflow consistent reduces condensation-driven corrosion.

Leveraging Farmonaut’s Technology for Agricultural Equipment Maintenance and Productivity

Farmonaut is revolutionizing agricultural operations by empowering farmers, agribusinesses, and government bodies with advanced, satellite-driven monitoring and management tools. Let’s see how the platform can boost farm workshop safety and maximize your operational efficiency:

- Real-Time Crop Health Monitoring: Farmonaut’s platform employs multispectral satellite imagery and AI to not only monitor fields for crop stress but also pinpoint areas requiring equipment maintenance. By scheduling servicing in sync with crop cycles, you minimize the risk of breakdowns during critical periods.

- Fleet and Resource Management: Maximize the productivity of your farm fleet. By tracking machinery usage and health, you can plan timely workshop maintenance and prioritize repairs, improving the overall longevity of agricultural equipment.

- AI-Driven Advisory: Jeevn AI Advisory System helps you schedule preventive maintenance, understand weather risks that may affect equipment, and plan the use of workshop resources efficiently.

- Blockchain-Based Traceability: If you supply agricultural produce to food chains or textile mills, ensuring tamper-proof records of machine-servicing cycles now becomes easier with Farmonaut’s blockchain-driven traceability modules. Audit trails help prove compliance in case of insurance claims or certifications.

- API Integration for Developers: Farmonaut offers versatile API access and detailed developer documentation for seamless integration of farm data into your ERP or workshop management solutions, streamlining digital operations.

- Carbon Footprinting: By calculating direct and indirect emissions from vehicle operations and workshop activities, you can adopt greener maintenance strategies. Learn more at Farmonaut Carbon Footprinting.

- Large-Scale Farm Operations: For farm managers operating vast estates, the Farmonaut Large Scale Farm Management suite enables centralized workshop scheduling, automated alerts for machinery repair dates, and audit logs for compliance.

Ready to digitize your farm workshop for tomorrow’s agriculture? Download the Farmonaut App today and experience the power of precision farm management tools!

Farmonaut Subscription Plans

Frequently Asked Questions (FAQ)

-

What’s the ideal size for a farm workshop?

The ideal size depends on your largest piece of machinery and available space on the farmstead. Aim for ample maneuvering space, at least 1.5 times the length and width of the largest equipment, plus space for benches and storage. -

How often should we check fire extinguishers and safety equipment?

Conduct monthly inspections of extinguishers, first aid kits, and emergency lighting. Log every check and replace expired or used items immediately. -

How can I prevent rust on farm tools in humid climates?

Clean and oil tools regularly, use silica packs in tool drawers, and store sensitive tools in airtight containers. Regular ventilation and cleaning routines are key. -

What’s the best way to organize small workshop parts and tools?

Use labeled bins, shadow boards, and mobile tool carts. Group tools by function and frequency of use, and always return them after each job. -

Why is tool cleaning important for workshop safety?

Dirty tools are harder to handle, more prone to slips, and may hide defects or cracks. Clean tools uphold safety and ensure optimal performance. -

Can digital technology improve workshop safety?

Absolutely. Platforms like Farmonaut can identify equipment readiness via sensors and usage records, schedule preventive maintenance, and automate reminders—ensuring timely action and reducing risk. -

What should I include in an emergency protocol sheet?

Fire escape routes, first aid contacts, hazard-specific instructions (chemical, electrical, mechanical), and lockout/tagout steps. Place these sheets in every workshop zone.

Conclusion: Establishing a Safe and Productive Farm Workshop

A strategically designed and meticulously managed farm workshop is an investment that pays substantial dividends across operational productivity, equipment longevity, and workplace safety. By focusing on:

- Farm workshop design that accommodates the largest machinery and ensures easy movement

- Tool storage and organization systems that minimize job interruption and risk

- Proactive equipment maintenance protocols including preventing rust, cleaning, and regular inspections

- Implementation of safety protocols—from PPE to emergency exits—ensuring a culture of awareness and rapid response

- Leveraging digital tools like Farmonaut for remote equipment checks, scheduling, and asset optimization

We stand to dramatically reduce both risk and cost, while also safeguarding the future of our agricultural operations. With knowledge, systematic organization, and commitment to ongoing improvement, your farm workshop will serve as the engine room behind every bountiful harvest.

Explore more about sustainable, precision agriculture solutions and keep your farm moving forward—only with Farmonaut!